1. Introduction to 3D Printing Filament

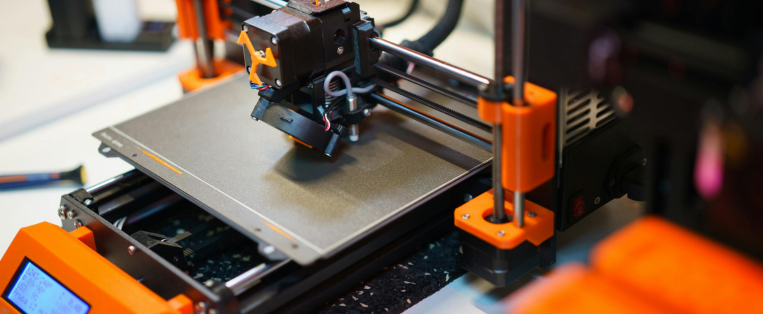

What is a 3D Printer Filament?

3D printing filament is the core material used in 3D printing to create physical objects layer by layer. It comes in different materials, each offering unique properties suitable for specific applications.

Importance of Choosing the Right Filament for Your Project

Selecting the appropriate 3D printing filament ensures optimal print quality, strength, and durability. The right filament can impact the efficiency of printing and the final product’s aesthetics and functionality.

Overview of 3D Printer Filament Types

Filaments vary in composition, print temperature, flexibility, and durability. Common types include ABS 3D printer filament, PLA, PETG, TPU, and metal-infused filaments.

2. Types of 3D Printer Filament and Their Applications

ABS 3D Printer Filament: Strengths, Weaknesses, and Best Use Cases

- Strong, impact-resistant, and heat-resistant

- Ideal for automotive, mechanical, and industrial applications

- Requires a heated print bed for successful printing

PLA, PETG, TPU, and Specialty Filaments

- PLA: Eco-friendly, easy to print, and great for beginners

- PETG: Stronger than PLA, water-resistant, and suitable for functional parts

- TPU: Flexible and ideal for soft-touch applications like phone cases

- Specialty filaments: Carbon fiber, wood, and glow-in-the-dark filaments

Metal 3D Printing Filament: Exploring High-Strength Printing Options

- Contains metal particles for enhanced strength

- Common in industrial 3D printer applications

- Used for 3D printing aircraft parts and 3D printing for automotive parts

3. Best 3D Printing Filament Choices for Different Needs

Filaments That Are Easy to Print

- PLA is the top choice due to its ease of use

- Compatible with popular models like Bambu Lab 3D Printer and Ultimaker 3D Printer

Affordable Filament Options

- Best budget 3D printer options work well with PLA and PETG

- Consider the Voron 3D Printer for a budget-friendly DIY approach

Rated 3D Printer and Its Compatible Filaments

- Best rated 3D printer models often support various filaments

- Look for printers with multi-material compatibility

4. Filament Storage and Maintenance for Optimal Performance

How to Store Filaments to Avoid Moisture Issues

- Keep filaments in airtight containers with desiccants

- Store in a dry, cool place to prevent brittleness and clogs

Troubleshooting 3D Printing Problems Caused by Filament Issues

1. Filament Not Extruding / Under-Extrusion

Cause: Moist filament, partial clogs, or filament diameter inconsistency.

Fix:

- Dry filament using a filament dryer or oven (50–60°C).

- Clean the nozzle with a cold pull or needle.

- Check filament diameter matches printer settings (1.75mm or 2.85mm).

2. Stringing / Oozing

Cause: Wet filament or incorrect retraction settings.

Fix:

- Dry the filament thoroughly.

- Increase retraction distance or speed in slicer settings.

- Lower printing temperature slightly to reduce oozing.

3. Nozzle Clogging

Cause: Dusty, low-quality, or moisture-absorbed filament.

Fix:

- Use high-quality filament with tight diameter tolerance.

- Store filament in airtight containers with desiccants.

- Perform hot/cold pulls to clean the nozzle.

4. Layer Shifting or Weak Layers

Cause: Brittle or uneven filament causing skips or tension.

Fix:

- Replace filament if it snaps easily or feels rough.

- Check for proper filament path—ensure no tangling or tension.

- Use fresh filament stored in dry conditions.

5. Inconsistent Extrusion

Cause: Diameter variation or foreign particles in filament.

Fix:

- Use premium-grade filament from reliable brands.

- Inspect filament visually before use.

- Adjust extruder tension if filament is slipping.

6. Grinding or Clicking Extruder

Cause: Filament too hard or soft, or obstructed path.

Fix:

- Clean extruder gears.

- Use filament with correct hardness for your printer.

- Check for filament knots or bends that block feeding.

7. Poor Adhesion to Bed (Warping / Curling)

Cause: Wet filament or extrusion inconsistency.

Fix:

- Dry filament to improve first layer bonding.

- Ensure the bed is clean, level, and at the correct temperature.

- Use adhesion aids like glue sticks or PEI sheets.

5. 3D Printing Filament for Specialized Applications

Automotive Parts: High-Temperature-Resistant Filaments

- ABS and carbon-fiber-infused filaments are ideal

- Used for 3D printing for car parts and engine components

Aircraft Parts: Lightweight and High-Strength Filaments

- Metal-infused and high-performance nylon filaments used

- Common in aerospace engineering applications

Custom Manufacturing and Prototyping

- 3D printing parts allows businesses to prototype efficiently

- Used in 3D printed industrial parts production

6. Choosing the Right 3D Printer for Filament-Based Printing

Best 3D Printer 2024 for Filament-Based Projects

- Best 3D printer 2024 models include multi-material support

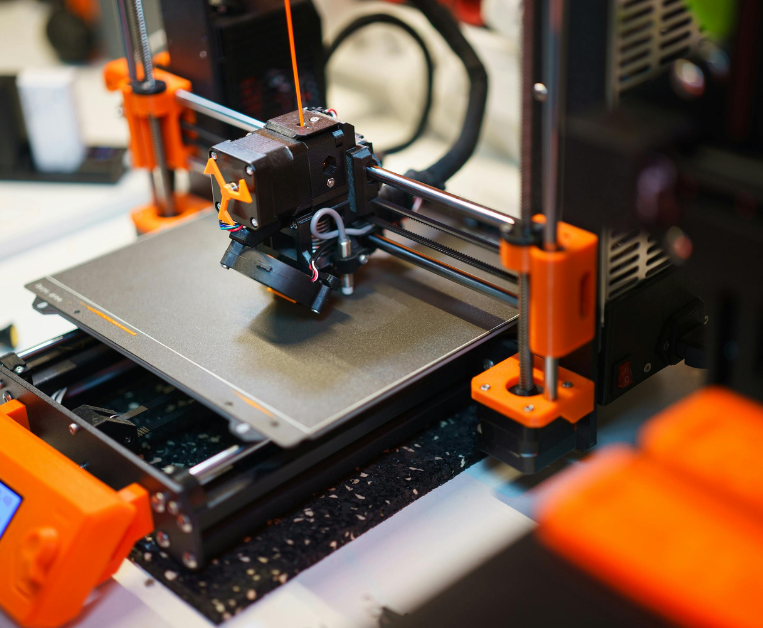

- Look for features like auto-bed leveling and direct drive extruders

Comparing Bambu Lab 3D Printer, Ultimaker 3D Printer, and Voron 3D Printer

- Bambu Lab X1 Carbon 3D Printer: High-speed and precise

- Ultimaker 3D Printer: Versatile and user-friendly

- Voron 3D Printer: Best for DIY enthusiasts

Industrial 3D Printer vs. 3D Printer for Kids

- Industrial 3D printer supports large-scale production

- 3D printer for kids focuses on ease of use and safety

7. Innovations in 3D Printing Filament Technology

Fastest 3D Printer and Its Impact on Filament Consumption

The choice between FPGA or Microcontroller depends on your project:

- Fastest 3D printer technologies increase efficiency

- Requires consistent filament supply and optimal settings

Printing Metal 3D Printer: The Rise of Metal-Infused Filaments

- Printing metal 3D printer uses filaments with metal particles

- Enables durable and functional metal part production

Bamboo 3D Printing – Exploring Eco-Friendly Filament Options

- Bamboo 3D printing and bamboo 3D printer use sustainable materials

- Reduces environmental impact in 3D printing service applications

8. Where to Buy and How to Use 3D Printer Filament

How to Use a 3D Printer Effectively with Different Filaments

- Adjust temperature settings according to filament types.

- Use a proper print surface to improve adhesion

3D Modeling for 3D Printing: Preparing Designs for Optimal Filament Use

- Ensure models are optimized for filament-based printing

- Use 3D print design software like Fusion 360 and Tinkercad

How to 3D Print with Various Filament Types

- Experiment with settings for different materials

- Avoid common issues by fine-tuning speed and cooling

9. Conclusion and Future of 3D Printing Filament

- Sustainable filaments are on the rise

- New composite materials enhance durability and flexibility

The Growing Market of 3D Printing Jobs

- 3D printing jobs are expanding in multiple industries

- Demand for skilled professionals is increasing

Recommendations for Beginners and Professionals

- Start with PLA and progress to advanced filaments

- Invest in high-quality 3D printing software for better results

3D Printing Filament FAQs

Q1: What is 3D printing filament?

A: 3D printing filament is the thermoplastic material used in FDM (Fused Deposition Modeling) 3D printers. It comes in spools and is melted layer by layer to create 3D objects.

Q2: What are the most common types of filaments?

A: The most popular filaments are PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), TPU (Thermoplastic Polyurethane), and Nylon.

Q3: Which filament is best for beginners?

A: PLA is the most beginner-friendly filament. It’s easy to print, requires low temperatures, and doesn’t warp easily.

Q4: What diameter filaments are available?

A: The two standard diameters are 1.75mm and 2.85mm (often called 3mm). Always check your printer specifications before buying filament.

Q5: Why is my filament breaking or brittle?

A: This usually happens when the filament has absorbed too much moisture. Drying it in a filament dryer or low-temperature oven can restore usability.

Q6: Can I reuse or recycle filament?

A: Yes. Failed prints can be shredded and recycled using filament recyclers, though consistency may vary. Some companies also offer eco-friendly, recycled filament spools.