Before a physical prototype is ever constructed, FEA analysis software is essential in the field of digital engineering for assessing the effectiveness, safety, and performance of products. Whether you’re designing consumer goods, automotive parts, or aerospace components, finite element analysis (FEA) has become an essential aspect of the development process.

What Is FEA Analysis?

FEA analysis, short for finite element analysis, is a numerical method used to predict how a product or structure reacts to real-world forces such as heat, vibration, fluid flow, and physical stress. It divides complex geometries into smaller “elements” and solves equations across these elements to simulate behavior.

FEA is essential in:

- Structural analysis of load-bearing components

- Thermal simulation in electronics and energy systems

- Vibration and modal analysis in automotive and aerospace design

- FEA stress analysis for failure prediction

Why Use FEA Analysis Software?

Finite element analysis is a computational technique used to:

Finite element analysis, or FEA analysis for short, is a computational technique used to forecast how a building or product will respond to physical stress, heat, vibration, fluid movement, and other real-world forces. To simulate behavior, it breaks down complicated geometries into smaller “elements” and solves equations between them.

FEA is necessary in:

- Analysis of load-bearing components’ structures.

- Energy and electronics systems using thermal simulation.

- In the design of automobiles and aircraft, vibration and modal analysis.

- FEA stress analysis to forecast failure.

ANSYS FEA Analysis: Industry Standard

FEA analysis is one of the most commercial and powerful software available. It is widely used in the aerospace industry, automotive machinery, electronics, and power engineering devices and in heavy industries. It is well known for its intuitive interface and quick solution. Ansys FEA analysis delivers structural, thermal, electromagnetic and fluid related simulations.

Why engineers choose ANSYS:

It is highly precise and delivers non linear simulation results. It integrates easily with CAD and product lifecycle management tools. Cloud based high performance computation is also delivered by it. Moreover, it is fully designed for multiphysics simulations. From stress simulation of an aircraft fuselage part or the heat distribution in PCB, ANSYS offers unmatched depth, scalability and reliability.

Abaqus FEA Analysis: Advanced Research and Material Behavior

Abaqus FEA analysis part of Dassault Systemes SIMULIA suite. Ansys is broadly adopted in industry, Abaqus is often preferred in academia and research due to advanced material modeling and simulations.

Key Features of Abaqus:

- Exceptional for nonlinear material behavior

- Simulates hyperelastic, viscoelastic, and plastic deformation

- Strong focus on biomechanics and composite materials

- Integrates with Python for custom scripting

If you’re running simulations on rubber, biological tissues, or carbon fiber, Abaqus FEA analysis may be your best choice.

Free FEA Analysis Software: Worth It or Not?

While commercial FEA software offers powerful capabilities, free FEA analysis software is increasingly popular among students, startups, and hobbyists.

Popular Free/Open-Source Options:

- CalculiX: Powerful solver, often compared to Abaqus

- Elmer FEM: Great for multiphysics, especially fluid flow and electromagnetics

- Code_Aster: Developed by EDF (French energy giant), supports advanced FEA simulations

- SimScale (Free Tier): Cloud-based FEA and CFD with community support

- FreeCAD with FEM workbench: Ideal for simple mechanical design validation

But here’s a critical analysis:

- Pros: No licensing fees, large open-source community, great for learning

- Cons: Steep learning curve, limited GUI, lacks commercial support, and slow for complex or large assemblies

Free tools are ideal for small-scale projects or academic use but may not meet the reliability and compliance standards needed in industrial environments.

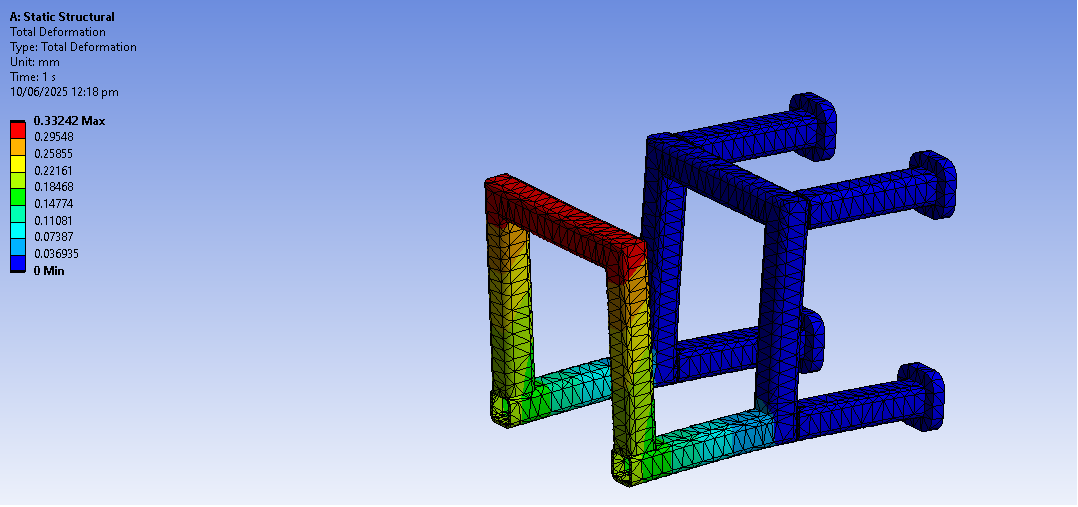

FEA Stress Analysis: Preventing Failure Before It Happens

FEA stress analysis is one of the most common applications of finite element analysis. It helps engineers predict where a component might fail under a specific load or repeated stress.

For example:

- In automotive, engineers use FEA to evaluate suspension parts under dynamic loading.

- In construction, it’s used to ensure that steel beams meet structural safety regulations.

- In electronics, it’s applied to analyze solder joint fatigue in PCBs due to thermal cycling.

Key Concepts in FEA Stress Analysis:

- Von Mises Stress: A commonly used failure criterion for ductile materials

- Fatigue Analysis: Predicting material lifespan under cyclic loads

- Factor of Safety (FoS): Indicates how much stronger a system is than it needs to be

Modern FEA analysis software makes it easy to visualize stress concentration areas, enabling better design decisions before any physical prototype is built.

FEA Structural Analysis: Simulating Real-World Performance

When it comes to analyzing full assemblies or large structures, FEA structural analysis becomes invaluable. Structural analysis isn’t just about stress it’s also about displacement, stiffness, modal frequencies, and buckling behavior.

Use Cases:

- Aerospace: Aircraft fuselage integrity under pressure

- Civil Engineering: Bridge load distribution

- Consumer Electronics: Drop testing smartphones virtually

By incorporating FEA structural analysis, companies save millions by reducing the number of failed prototypes and avoiding catastrophic real-world failures. Explore our FEA analysis services on our website!

FEA in Future: AI Integration and Cloud Simulation

As AI and machine learning continue to advance, the next wave of FEA analysis software will integrate predictive analytics to recommend design changes automatically. Additionally, cloud-based FEA platforms now allow simulations that once took hours to finish in minutes with distributed computing.

Key trends include:

- Topology Optimization

- Digital Twin Integration

- Real-time Simulation Feedback

Conclusion: Choosing the Right FEA Analysis Software

Selecting the right FEA analysis software depends on your application, budget, and team expertise. While ANSYS and Abaqus lead the commercial market with robust features and support, free FEA analysis software options are making simulation accessible to more people than ever.

Whether you’re a student, an engineer in a multinational corporation, or a startup innovator, understanding the capabilities and limitations of FEA tools will help you make smarter design decisions.

FAQs

Q1. First of all, what is finite element analysis, or FEA?

A: A computational technique called finite element analysis (FEA) is used to forecast how a product will respond to physical factors like heat, vibration, fluid movement, and other effects.

Q2: What kinds of issues can be resolved via FEA?

A: FEA is capable of analyzing fatigue life, fluid interactions, thermal effects, vibrations, and structural stress. It is employed for failure prevention, design optimization, and durability testing.

Q3: What FEA software do you utilize?

A: Depending on the nature and complexity of the project, we employ industry-standard software like ANSYS, Abaqus, SolidWorks Simulation, and COMSOL.

Q4: Do we use FEA to help you optimize your product?

A: Definitely. To find stress spots, save weight, increase durability, and offer economical design suggestions, we employ FEA.

Q5: Do you offer thorough reports?

A: For your internal or client reviews, we do offer thorough reports with illustrations, stress plots, deformation graphs, and engineering findings.

Q6: What is the duration of a FEA project?

A: A project’s duration can vary from a few days to two weeks, depending on its complexity. For critical projects, we also provide expedited services.