Introduction

Manufacturing has transformed over the years, with businesses now requiring faster, cost-effective, and precise methods to produce complex parts. One such powerful process is metal injection molding (MIM). Combining the versatility of plastic injection molding with the strength of powdered metallurgy, MIM enables the production of high-performance metal parts in large or small volumes.

In this article, we’ll break down the process, benefits, applications, and compare it with other molding techniques like plastic, rubber, and reaction injection molding. We’ll also highlight leading injection molding companies, industry jobs, and regional players like Texas Injection Molding in Houston, TX.

What is Metal Injection Molding (MIM)?

Metal Injection Molding is a manufacturing process that blends fine metal powders with a binder material to create a feedstock. This mixture is injected into a mold cavity, shaped, and then undergoes debinding and sintering to form dense, strong metal components.

It is particularly useful for producing small, intricate parts that would be too expensive or complex to machine.

Process of Metal Injection Molding

- Feedstock Preparation: Fine metal powders are mixed with polymer binders.

- Injection Molding: The feedstock is injected into a mold using a machine similar to a plastic injection molding press.

- Debinding:The binder material is removed.

- Sintering: The component is heated at high temperatures to densify the metal.

The result is a part that combines the strength of metal with the design flexibility of injection molding.

Alt Text: Metal Injection Molding

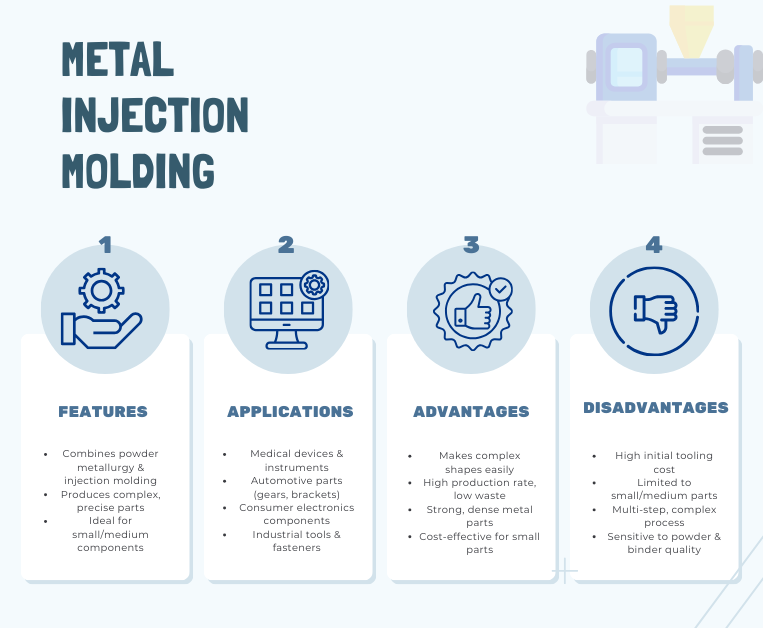

Advantages of Metal Injection Molding

- Complex geometries: Can create detailed shapes without secondary machining.

- Material efficiency: Minimal waste compared to machining.

- Cost-effective for volume: Competitive pricing for medium-to-high production runs.

- Mechanical strength: Properties comparable to wrought metals.

- Scalability: Suitable for both prototype injection molding and production runs.

Applications of Metal Injection Molding

- Automotive Injection Molding: Production of gears, brackets, and safety components.

- Medical Devices: Surgical instruments, orthodontic brackets, implants.

- Electronics: Connectors, housings, precision components.

- Aerospace & Defense: Lightweight yet durable metal parts.

Metal Injection Molding vs. Other Injection Molding Techniques

- Plastic Injection Molding:

Uses polymers instead of metal powders, ideal for mass-producing plastic components at low cost. - Rubber Injection Molding:

Involves molding elastomers for seals, gaskets, and vibration control applications. - Reaction Injection Molding (RIM):

Uses chemical reactions of two liquid components (like polyurethanes) to create lightweight yet strong parts, often in automotive panels. - Low Volume Injection Molding:

Suitable for small production runs or prototypes before committing to mass production.

Each of these processes has its place, but metal injection molding stands out when strength, complexity, and precision are required.

Industry and Regional Insights

- Injection Molding Companies: Many global firms now specialize in MIM along with plastic and rubber solutions.

- Injection Molding Jobs Near Me: With the rise in manufacturing demand, opportunities exist for engineers, operators, and quality specialists in injection molding industries worldwide.

- Texas Injection Molding (Houston, TX): A recognized company providing services for plastics and specialized molding solutions.

Critical Analysis of Metal Injection Molding

Strengths

- Combines flexibility of molding with mechanical properties of metal.

- Efficient for complex small-to-medium parts.

- Reduces material waste compared to machining.

Weaknesses

- Higher initial tooling costs compared to machining for small runs.

- Limited to small and medium-sized parts.

- Requires precise sintering control to avoid shrinkage issues.

Opportunities

- Expansion into automotive injection molding for EV components.

- Growing demand in medical and aerospace for miniaturized metal parts.

- Hybrid use with additive manufacturing for rapid prototyping.

Threats

- Competition from CNC machining for low-volume custom parts.

- Development of high-strength plastic injection molding materials reducing metal need.

- Economic downturns affecting large-scale industrial demand.

Conclusion

Metal injection molding is one of the most advanced methods for manufacturing small, complex, and high-strength components. While plastic injection molding, rubber injection molding, and reaction injection molding dominate their niches, MIM remains the best choice when durability and precision are critical.

As industries evolve especially automotive, aerospace, and medical the demand for MIM will continue to rise. For businesses, partnering with reliable injection molding companies ensures access to both traditional and advanced molding technologies.

FAQs

Q1. What materials are used in metal injection molding?

A: Stainless steel, titanium, nickel alloys, and cobalt-chrome are commonly used.

Q2. Is metal injection molding suitable for prototypes?

A: Yes, prototype injection molding allows testing before full production, though tooling costs can be high.

Q3. How does MIM compare to CNC machining?

A: CNC is better for low-volume, large parts, while MIM excels in high-volume, small, intricate components.

Q4. Can automotive parts be made with MIM?

A: Yes, automotive injection molding often uses MIM for gears, brackets, and safety components requiring high strength.

Q5. What’s the difference between plastic and metal injection molding?

A: Plastic injection molding uses polymers, while MIM uses metal powders. Plastic is cheaper but lacks the strength of metals.

Q6. Where can I find injection molding jobs near me?

A: Jobs are available in manufacturing hubs worldwide, especially in automotive, medical, and consumer electronics sectors.

Q7. Which companies are leaders in injection molding?

A: Both global injection molding companies and local firms (like Texas Injection Molding, Houston TX) provide specialized services depending on material and industry.