If you’re an engineer, a hobbyist, or just someone hunting for the right motor for your project, chances are you’ve heard the term “BLDC motor” thrown around. But what actually is it? And why is everyone obsessed with it?

So, What’s a BLDC Motor Anyway?

BLDC (Brushless DC Motor) is basically a smarter version of traditional motors. Old-school motors had physical brushes that wore out over time. BLDC motors ditch the brushes and use an electronic controller instead which means less breakdown, more efficiency.

Think of it like upgrading from a flip phone to a smartphone. Same basic function, way better technology.

Why Is Everyone Talking About It?

1. Efficiency Champion

These motors hit 85-90% efficiency. That means longer battery life and lower power bills. Whether it’s drones or electric cars, everyone wants that.

2. Built to Last

No brushes mean no friction, no wear and tear. These motors can run for years without needing replacement parts.

3. Small But Mighty

They’re lightweight yet pack serious torque. Perfect for robotics and portable devices where space is tight.

4. Precision Control Freak

Speed and position control? Spot on. Pair them with Hall effect sensors and you get surgical precision.

5. The Silent Worker

Low vibration, minimal noise. From home fans to hospital equipment they work quietly in the background.

Where Do You Actually Find These?

Look around electric motor BLDC are everywhere:

- Electric vehicles and e-bikes.

- Drones spinning their propellers.

- Industrial machines that need precision.

- Air conditioners and refrigerators.

- Robot arms and warehouse automation.

- Computer fans keep your laptop cool.

From consumer gadgets to heavy industry they’re trusted across the board.

What to Check Before You Buy?

Voltage and Current

Make sure your power supply and controller are compatible. Mismatched specs = wasted money.

KV Rating

- High KV = more speed (great for drones)

- Low KV = more torque (better for robotics and heavy loads)

Torque Needs

How much weight will it move? Is it static or dynamic load? Figure this out first.

Rotor Design

- Inner rotor = built for high-speed applications

- Outer rotor = designed for high-torque needs

Sensored vs. Sensorless

- Sensored = better low-speed control

- Sensorless = faster and cheaper

ESC Compatibility

Your motor and ESC need to match like a phone and its charger. Get this wrong and nothing works right.

Why the Market Is Booming

Electric motor BLDC demand is skyrocketing because:

- Electric mobility is exploding everywhere.

- Automation is taking over every industry.

- Energy efficiency isn’t optional anymore.

- Electronics are getting smaller, motors need to follow.

Bottom Line

BLDC motors aren’t just another tech upgrade, they’re the future of efficient machinery. Whether you’re building a DIY project, launching a startup, or scaling industrial operations, BLDC gives you performance, durability, and control all in one package.

Pro Tip: Get clear on what you need first speed or torque? What’s your budget? What’s the application? Then lock in your motor choice.

Electric Motor BLDC: The Smart Buyer’s Guide That Actually Makes Sense

If you’re an engineer, a hobbyist, or just someone hunting for the right motor for your project, chances are you’ve heard the term “BLDC motor” thrown around. But what actually is it? And why is everyone obsessed with it? In today’s smart electronics landscape, BLDC motors are a key component for building energy-efficient, intelligent, and performance-driven electronic systems.

So, What’s a BLDC Motor Anyway?

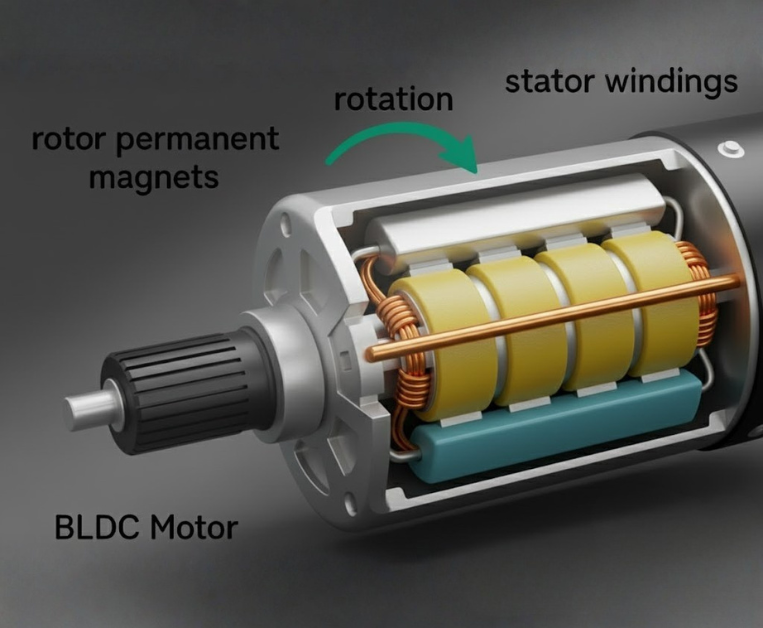

BLDC motor (Brushless DC Motor) is basically a smarter version of traditional motors. Old school motors had physical brushes that wore out over time. A brushless motor BLDC ditches the brushes and uses an electronic controller instead which means less breakdown, more efficiency. The BLDC motor operates on direct current but with electronic commutation, making it superior to conventional brushed designs.

Think of it like upgrading from a flip phone to a smartphone. Same basic function, way better technology.

Why Is Everyone Talking About It?

1. Efficiency Champion

These motors hit 85-90% efficiency. That means longer battery life and lower power bills. Whether it’s drones or electric cars, everyone wants that.

2. Built to Last

No brushes mean no friction, no wear and tear. These motors can run for years without needing replacement parts.

3. Small But Mighty

They’re lightweight yet pack serious torque. Perfect for robotics and portable devices where space is tight.

4. Precision Control Freak

Speed and position control? Spot on. Pair them with Hall-effect sensors and you get surgical precision.

5. The Silent Worker

Low vibration, minimal noise. From home fans to hospital equipment they work quietly in the background.

Where Do You Actually Find These?

Look around BLDC motors are everywhere:

- Electric vehicles and e-bikes

- Drones spinning their propellers

- Industrial machines that need precision

- Air conditioners and refrigerators

- Robot arms and warehouse automation

- Computer fans keeping your laptop cool

From consumer gadgets to heavy industry they’re trusted across the board.

What to Check Before You Buy?

Voltage and Current

Make sure your power supply and controller are compatible. Mismatched specs = wasted money.

KV Rating

- High KV = more speed (great for drones)

- Low KV = more torque (better for robotics and heavy loads)

Torque Needs

How much weight will it move? Is it static or dynamic load? Figure this out first.

Rotor Design

- Inner rotor = built for high-speed applications

- Outer rotor = designed for high-torque needs

Sensored vs. Sensorless

- Sensored = better low-speed control

- Sensorless = faster and cheaper

ESC Compatibility

Your motor and ESC need to match like a phone and its charger. Get this wrong and nothing works right. The BLDC motor controller (also called BLDC driver) is crucial for proper motor operation. It handles the electronic commutation that makes brushless motors work. Most 3 phase BLDC motors require a compatible three-phase controller for optimal performance.

Why Is the Market Booming?

BLDC motor demand is skyrocketing because:

- Electric mobility is exploding everywhere.

- Automation is taking over every industry.

- Energy efficiency isn’t optional anymore.

- Electronics are getting smaller, motors need to follow.

Bottom Line

BLDC motors aren’t just another tech upgrade, they’re the future of efficient machinery. Whether you’re building a DIY project, launching a startup, or scaling industrial operations, BLDC gives you performance, durability, and control all in one package.

Pro Tip: Get clear on what you need first speed or torque? What’s your budget? What’s the application? Then lock in your motor choice.

Frequently Asked Questions About BLDC Motors

Q1. What is the difference between a BLDC motor and a brushed DC motor?

A: The main difference is in commutation. A brushed DC motor uses physical brushes and a commutator to switch current, which creates friction and wear. A BLDC DC motor uses electronic commutation through a BLDC motor controller, eliminating physical contact. This makes the brushless motor BLDC more efficient (85-90% vs 75-80%), longer-lasting, and requires virtually zero maintenance compared to brushed motors.

Q2. What does KV rating mean in BLDC motors?

A: KV rating indicates how many RPM (revolutions per minute) the BLDC motor will spin per volt with no load. For example, a 1000KV motor on a 12V battery will spin at approximately 12,000 RPM. Higher KV means higher speed but lower torque, while lower KV means lower speed but higher torque. Choose based on your application: drones need high KV, robotics needs low KV.

Q3. Do I need a special controller for a BLDC motor?

A: Yes, absolutely. Every BLDC motor requires a BLDC driver or ESC (Electronic Speed Controller) to function. The BLDC motor controller handles the switching of current through the motor’s phases. Most motors use a 3 phase BLDC motor configuration, which requires a compatible three-phase controller. Make sure your controller voltage and current ratings match your motor’s specifications.

Q4. What is a 3 phase BLDC motor and why is it common?

A: 3 phase BLDC motor has three sets of stator windings arranged 120 degrees apart. This configuration provides smoother torque, better efficiency, and more precise control compared to single-phase or two-phase designs. Almost all modern brushless motor BLDC applications use three-phase designs because they offer superior performance and are easier to control with standard BLDC drivers.

Q5. Can a BLDC motor run without sensors?

A: Yes, BLDC motors can run in both sensored and sensorless modes. Sensorless BLDC DC motors use back-EMF (electromotive force) detection to determine rotor position, making them cheaper and simpler. However, they struggle at low speeds and startup. Sensored motors use Hall-effect sensors for precise position feedback, giving excellent low-speed control. Your BLDC motor controller must support the mode you choose.

Q6. What are the most common applications for BLDC motors?

A: BLDC motors dominate in applications requiring efficiency, precision, and reliability: electric vehicles and e-bikes, drones and UAVs, industrial automation and CNC machines, HVAC systems and compressors, robotics and AGVs, and computer cooling fans. The brushless motor BLDC design is preferred wherever long lifespan and low maintenance are critical. With the right BLDC driver, these motors can be adapted to almost any precision motion application.