Introduction

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry by enabling precise, automated, and highly repeatable processes. Among the wide range of applications, ceramic CNC machining stands out due to its ability to create strong, heat-resistant, and high-performance parts.

From CNC machine wood cutting to CNC machine metal shaping, these machines are everywhere in workshops, industries, and even training institutes. But how do they work, what makes them different, and which type of CNC machine suits your needs? Let’s break it down.

What is meant by CNC Machine?

At its core, a CNC machine is a computer-controlled manufacturing tool that moves tools or materials with extreme accuracy. Instead of manual machining, CNC automates the process, following programmed instructions.

- Inputs: A digital design (CAD file).

- Process: The CNC machine interprets the file and guides cutting, drilling, milling, or shaping.

- Output: A finished part with high accuracy.

This automation reduces human error, increases speed, and allows mass production of complex parts.

Ceramic CNC Machining

Ceramics are widely used in aerospace, electronics, and medical industries due to their heat resistance, durability, and strength. However, ceramics are brittle and challenging to machine using traditional methods.

Ceramic CNC machining solves this by:

- Using specialized CNC cutting tools (like diamond-coated cutters).

- Allowing complex geometries without breaking the ceramic.

- Producing parts like insulators, biomedical implants, and aerospace components.

Benefits of Ceramic CNC Machining

- High precision and tolerance control.

- Ability to create small, detailed parts.

- Consistency in mass production.

- Strong, heat-resistant finished components.

Types of CNC Machines

1. CNC Lathe Machine

A CNC lathe machine rotates the workpiece while cutting tools shape it. These machines are widely used for:

- Cylindrical parts

- Threads and shafts

- Automotive and aerospace components

They offer excellent speed and accuracy compared to manual lathes.

2. CNC Machine for Wood

Woodworking has become more efficient with CNC machine wood cutting tools. These machines are perfect for:

- Furniture making

- Decorative panels

- Wooden art and engravings

Using a CNC machine for wood, craftsmen achieve consistency in design, even on complex patterns. Popular models like CNC machine X Carve are popular among hobbyists and small businesses.

3. CNC Machine Metal

Metal machining requires strength and precision. A CNC machine metal system can cut, drill, or shape materials like steel, aluminum, and titanium. Industries like automotive, aerospace, and defense rely on these machines for critical components.

4. Small CNC Machine

Not every application requires a large industrial setup. A small CNC machine is suitable for workshops, labs, and small-scale businesses.

Advantages:

- Lower cost

- Space-saving design

- Great for prototyping

Alt tag: CNC Machining

5. Mini CNC Machine

A step smaller than small CNCs, the mini CNC machine is popular among hobbyists and educational setups. They can engrave, cut, or mill plastics, wood, and light metals.

Best For:

- DIY projects

- Jewelry making

- Educational demonstrations

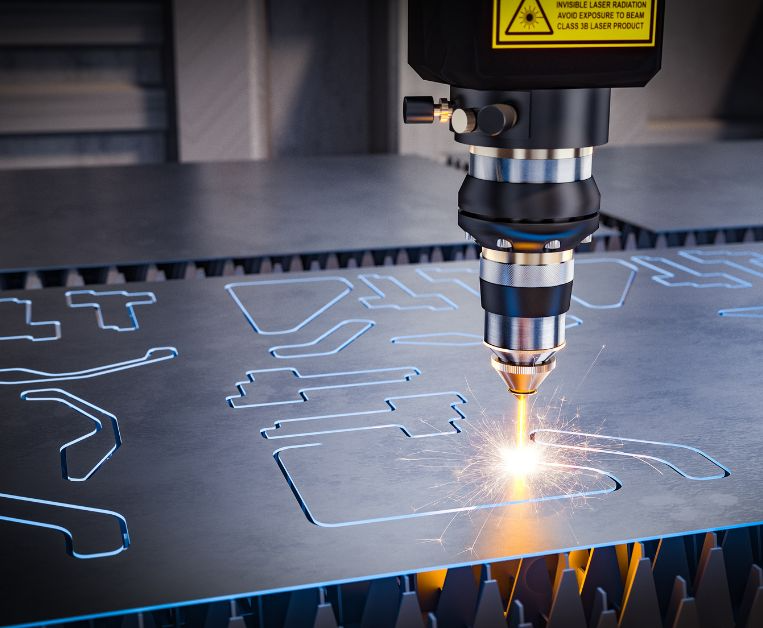

6. Laser CNC Machine

Instead of cutting with a drill or mill, a laser CNC machine uses a high-powered laser beam. This allows for ultra-precise cuts and engravings on:

- Wood

- Plastic

- Metal sheets

- Acrylics

Laser CNC machining is widely used in signage, decorative items, and electronics casing.

7. CNC Cutting Machine

The term CNC cutting machine generally refers to machines that cut materials like sheet metal, wood, or composites. It includes plasma cutters, waterjet cutters, and laser cutters.

Applications:

- Cutting complex patterns in sheets

- Automotive panels

- Industrial fabrication

8. Training CNC Machine

Learning CNC machining is crucial for engineers and technicians. A training CNC machine is designed for educational purposes, offering hands-on experience without the high cost of industrial machines.

Benefits:

- Safe learning environment

- Affordable machines for schools and universities

- Practical skills for real-world applications

Case Study 1: Ceramic CNC Machining in Aerospace

Problem

An aerospace company needed ceramic turbine blade inserts that could withstand extreme heat and pressure. Traditional machining methods caused cracking and material wastage due to ceramic’s brittle nature.

Solution

The company implemented ceramic CNC machining using diamond-coated cutters on a CNC cutting machine. With computer precision and controlled feed rates, they successfully:

- Reduced cracking issues.

- Achieved tighter tolerances.

- Increased production yield by 30%.

Result: High-quality, heat-resistant ceramic parts for jet engines were produced efficiently and consistently.

Alt tag: cnc machining

Case Study 2: CNC Machine for Wood in Furniture Manufacturing

Problem

A custom furniture workshop faced inconsistent quality when cutting detailed designs by hand. Manual processes were slow, inaccurate, and limited in complexity.

Solution

The workshop invested in a CNC machine for wood, specifically an X Carve CNC machine, to automate cutting and engraving. With digital design files, they could:

- Produce complex wooden patterns.

- Improve precision and consistency.

- Reduce manual labor time by 40%.

Result: The business expanded product offerings to include detailed carvings and decorative panels, boosting sales and customer satisfaction.

Case Study 3: Combining CNC Lathe Machine & Training CNC Machine for Automotive Industry

Problem

An automotive parts manufacturer needed to train new engineers quickly while maintaining high production standards for metal shafts and gears. Lack of training led to costly errors on full-scale CNC lathe machines.

Solution

They deployed training CNC machines in their in-house learning center for engineers to practice programming and operations. After training, workers transitioned to production-level CNC lathe machines to create precision metal components.

Result:

- Reduced operator errors by 50%.

- Faster onboarding of engineers.

- Maintained high-quality standards in gear and shaft production.

Conclusion

CNC machining is at the heart of modern manufacturing, and ceramic CNC machining has opened doors to producing high-performance parts that traditional machining couldn’t achieve. From CNC lathe machines shaping automotive parts to CNC machines for wood creating elegant furniture, and laser CNC machines delivering precision engravings each machine serves a unique role.

Whether you’re a hobbyist exploring a mini CNC machine, a professional running a CNC cutting machine, or a student learning on a training CNC machine, the future of CNC technology promises greater precision, efficiency, and innovation.

FAQs

Q1: What is meant by CNC machine?

A: A CNC machine is a computer-controlled tool that automates cutting, milling, drilling, and shaping processes for high precision.

Q2: What is ceramic CNC machining used for?

A: It is used to produce heat-resistant and strong parts like biomedical implants, aerospace components, and electronic insulators.

Q3: What is the difference between a small CNC machine and a mini CNC machine?

A: A small CNC machine is designed for workshops and prototyping, while a mini CNC machine is compact, affordable, and mainly used by hobbyists and students.

Q4: Can CNC machines cut wood and metal both?

A: Yes, but usually different machines are optimized for wood (lighter, faster spindles) and metal (heavier, more rigid frames).

Q5: What is a CNC lathe machine?

A: A CNC lathe machine shapes cylindrical parts by rotating the workpiece and using cutting tools for precision.

Q6: What is a training CNC machine?

A: A training CNC machine is a simplified, affordable version used in schools and institutes to teach CNC programming and operations.