Printed Circuit Boards (PCBs) are the backbone of every modern electronic device from smartphones and medical equipment to aerospace and industrial machines. A high quality PCB design is not just about connecting components; it’s about ensuring performance, reliability, and efficiency over the product’s lifetime. Poor PCB layouts can lead to overheating, signal interference, or even complete product failure.

Why It Matters?

When it comes to electronic products, quality is non-negotiable. A well-designed PCB ensures:

- Signal Integrity: Preventing noise and cross-talk in high-speed circuits.

- Thermal Management: Controlling heat dissipation for longer component life.

- Space Optimization: Efficiently using board area for compact, lightweight products.

- Reliability: Minimizing failure risks and ensuring compliance with industry standards.

Whether you are building consumer gadgets or mission-critical aerospace systems, investing in quality PCB design directly impacts your product’s performance and customer satisfaction.

High Quality PCB Design Guide: Key Considerations

Here’s a step-by-step guide to achieving a high quality PCB layout design:

1. Define Requirements Clearly

Before starting, outline electrical, mechanical, and thermal requirements. This avoids costly redesigns later.

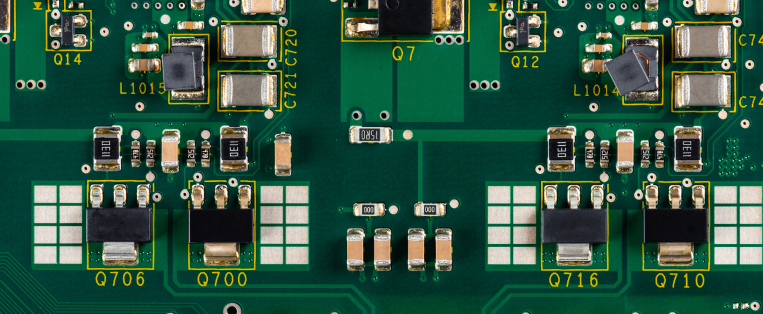

2. Component Placement Strategy

- Place high-speed components close to each other.

- Keep analog and digital sections separate.

- Position power supply parts strategically to reduce interference.

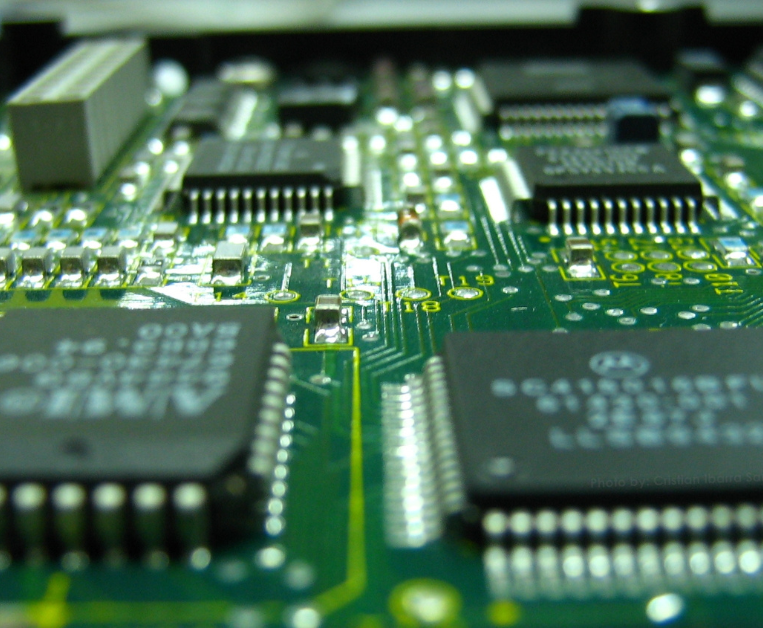

3. Signal Routing Best Practices

- Use controlled impedance traces for high-frequency signals.

- Keep trace lengths consistent to avoid timing mismatches.

- Route power and ground properly to reduce noise.

4. Power & Ground Planes

A solid ground plane is crucial for noise reduction. Power planes should be layered carefully to ensure stable current flow.

5. Thermal Design

For high-power devices, thermal vias, heat sinks, and copper pours help prevent overheating.

6. Design for Manufacturability (DFM)

Your PCB design should comply with manufacturing tolerances. This ensures smooth, cost-effective production.

Professional High Quality PCB Layout and Design Services

Not every company has the in-house expertise or tools for complex PCB projects. That’s where high quality PCB layout and design services come in. These services offer:

- Expert engineers with years of PCB experience.

- Advanced simulation tools to test signal integrity and thermal behavior.

- Compliance with IPC standards for safety and reliability.

- Prototyping & mass production support to speed up time-to-market.

By outsourcing, businesses save time, reduce errors, and get access to the latest design technologies.

Benefits of Choosing High Quality PCB Layout Design Services

- Reduced Risk of Failure: Professional designs minimize costly errors.

- Optimized Performance: Ensures smooth functioning of high-speed, high-power circuits.

- Scalability: Services adapt to projects from simple consumer electronics to complex defense systems.

- Cost Efficiency: Better design reduces rework and manufacturing waste.

Conclusion

A high quality PCB design is the foundation of reliable, efficient, and durable electronic products. Following a high quality PCB design guide ensures your product meets both technical and business goals.

FAQs

Q1: What is high quality PCB design?

A: A high quality PCB design ensures efficient component placement, signal integrity, thermal management, and compliance with industry standards for reliable performance.

Q2: Why is it is important?

A: It reduces risks of overheating, interference, and product failure, while improving durability, efficiency, and manufacturing success rates.

Q3: What are high quality PCB layout and design services?

A: These are professional services that provide expert PCB engineers, advanced tools, and manufacturing-ready designs for industries like consumer electronics, automotive, aerospace, and medical.

Q4: How do I choose the best PCB design service?

A: Look for providers with IPC-compliant designs, experience in your industry, strong client reviews, and capabilities in prototyping and large-scale production.

Q5: What factors should I consider in a making quality PCB design?

A: Key factors include clear requirement definition, optimized component placement, efficient signal routing, power & ground planes, and thermal management.