Robotics has become one of the most influential fields in modern engineering, transforming industries from manufacturing to healthcare. Among its many innovations, the extendable robotic arm stands out as a versatile tool for automation. Unlike traditional robotic arms with fixed lengths, extendable arms provide added reach and flexibility, making them ideal for applications that demand adaptability in compact spaces.

In this blog, we will break down how to design an extendable robotic arm, covering the principles, mechanical structure, materials, electronics, and control systems required to build a functional prototype.

1. Understanding Extendable Robotic Arms

An extendable robotic arm is designed to increase its working range while maintaining stability and precision. These arms are often seen in:

- Industrial robots for assembly lines.

- Medical robots for minimally invasive surgeries.

- Space exploration robots like the Canadarm used in satellites and the ISS.

- Service robots for inspection, rescue, or logistics.

What makes them unique is the telescopic or sliding extension mechanism, allowing the arm to reach areas a fixed-length robotic arm cannot.

2. Key Considerations Before Designing

Before jumping into the actual design, you must define the purpose of your extendable robotic arm. Ask yourself:

- What is the payload capacity? (How much weight will it lift?)

- What is the maximum extension length required?

- Will it work in hazardous, outdoor, or indoor environments?

- What precision or accuracy is expected?

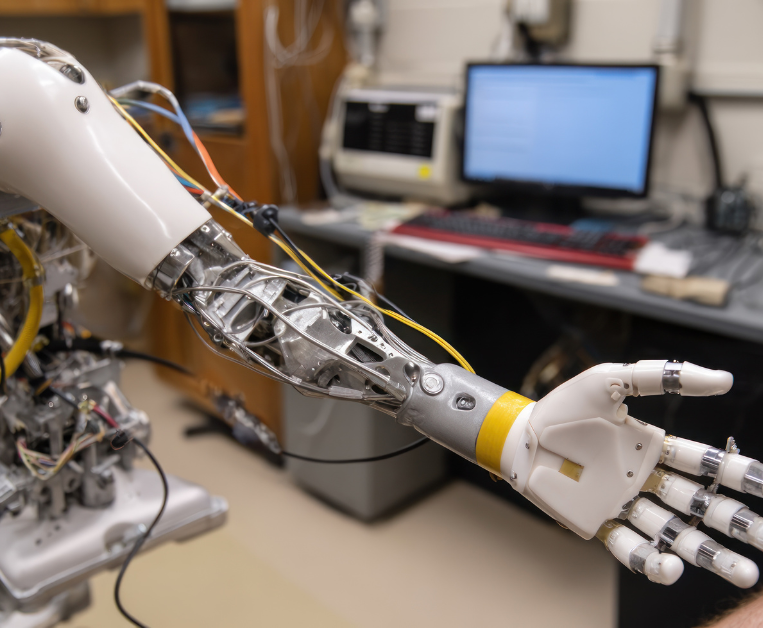

3. Mechanical Design of Extendable Robotic Arm

The mechanical structure is the backbone of the robotic arm.

a. Extension Mechanism

The two most common types are:

- Telescopic Design – Uses nested tubes that slide into each other, extending like a telescope.

- Sliding Rail Design – Uses linear rails and bearings to extend sections smoothly.

Both designs require low-friction materials and often rely on gears, belts, or screw-driven actuators for controlled extension.

b. Joints and Degrees of Freedom

Extendable robotic arms must have joints (rotational or prismatic) to move like a human arm. The more degrees of freedom (DOF) you add, the more complex and versatile the arm becomes. Typical arms range from 3 to 7 DOF.

c. Materials Selection

Lightweight but strong materials such as aluminum, carbon fiber, or composites reduce stress.

For heavy-duty applications, steel alloys provide higher strength but at the cost of weight.

4. Actuation System

Actuators are the muscles of the robotic arm. Depending on application, you can use:

- Electric Motors (DC/Stepper/Servo Motors): Precise, commonly used in small- to medium-load robotic arms.

- Hydraulic Actuators: Best for heavy industrial arms requiring high force.

- Pneumatic Actuators: Ideal for lightweight and fast response applications.

For an extendable arm, linear actuators or rack-and-pinion drives are often used to control telescoping motion.

5. Sensors and Feedback System

Accuracy and stability in an extendable robotic arm depend heavily on sensors. Key options include:

- Encoders – Track joint rotation and position.

- Load Sensors – Prevent overload and damage.

- Proximity/Infrared Sensors – Help in obstacle detection.

- IMUs (Inertial Measurement Units) – Measure orientation and movement.

These sensors provide real-time feedback to the control system, ensuring precision.

6. Control System and Programming

The control system acts as the brain of the robotic arm.

a. Microcontrollers and Processors

- Arduino or Raspberry Pi for simple prototypes.

- Industrial PLCs (Programmable Logic Controllers) for complex automation.

b. Control Algorithms

- PID Controllers maintain smooth motion.

- Inverse Kinematics ensures the robotic arm reaches a target point accurately.

- Machine Learning Integration enables adaptive movement for advanced robotics.

c. Human-Machine Interface (HMI)

Control can be achieved via:

- Joysticks

- Touchscreen panels

- Wireless controllers

- Pre-programmed routines

7. Power Supply and Management

The power system depends on your actuator type:

- Electric motors require batteries or AC/DC power supplies.

- Hydraulics/Pneumatics need pumps, compressors, and fluid reservoirs.

A balance between power density and weight is critical. For mobile robots, lithium-ion batteries are common due to high energy density.

8. Safety and Reliability

Since robotic arms often work near humans or in critical environments, safety is crucial.

- Emergency Stop Systems should be included.

- Limit switches prevent over-extension.

- Fail-safe programming ensures the arm stops gracefully in case of malfunction.

9. Prototyping and Testing

After designing, create a scaled-down prototype using 3D printing, aluminum profiles, or modular kits. Test for:

- Payload performance

- Extension smoothness

- Stability during maximum reach

- Heat dissipation in motors

Iterative testing ensures that the final product meets all safety and functional requirements.

10. Real-World Applications of Extendable Robotic Arms

- Automotive Industry: Extendable robotic arms are heavily used in the automotive industry for assembly, welding, and painting.

- Medical Industry: In the medical industry, robotic arms assist in minimally invasive surgeries and rehabilitation devices.

- Automatic Retail Industry: Retail automation also benefits from robotic mechanisms similar to extendable arms, especially in automatic vending machines.

Conclusion

Designing an extendable robotic arm is a multidisciplinary task that combines mechanical engineering, electronics, programming, and safety protocols. By carefully planning the mechanical structure, extension mechanism, actuation system, and control algorithms, you can create a robotic arm that is not only functional but also reliable and scalable for real-world applications.

Whether you are building a simple educational prototype or an industrial-grade robotic arm, the same core design principles apply: strength, precision, adaptability, and safety.

FAQs

Q1: What is an extendable robotic arm used for?

A: Extendable robotic arms are used in industries, healthcare, space, and service robots where flexibility and long reach are required.

Q2: Which materials are best for designing a robotic arm?

A: Lightweight and strong materials like aluminum, carbon fiber, or composites are ideal for most applications.

Q3: How many degrees of freedom should a robotic arm have?

A: It depends on the application; simple tasks may need 3 DOF, while complex operations may require up to 7 DOF.

Q4: Which actuators are best for extendable robotic arms?

A: Electric motors are common for small arms, while hydraulic actuators are used for heavy-duty industrial robots.

Q5: Can I build a robotic arm using Arduino?

A: Yes, Arduino is a great choice for prototyping and small-scale extendable robotic arms due to its easy programming and sensor compatibility.