What if safety could be designed into the system, built right into the machines, the workplace layout, or even the software? That’s not just a nice thought; it’s real, and it’s called engineering controls. So let’s answer the burning question: what are engineering controls, and why should engineers, managers, and even factory floor workers care?

Spoiler alert: It’s not just about putting up warning signs, it’s about eliminating the problem altogether!

To put it simply, what engineering controls? They are physical or mechanical changes to tools, systems, environments, or processes that reduce or eliminate exposure to hazards.

Unlike administrative controls (like training) or personal protective equipment (PPE), engineering controls tackle the danger at the source. They don’t just warn you about the lion in the room, they put a cage around it.

Think of them as the superheroes of workplace safety, doing their job silently and consistently in the background.

Classic Engineering Controls in Real Life

Let’s bring this concept to life with some practical and fun examples.

1. Fume Hoods in Engineering Labs

In chemical or materials engineering labs, fume hoods suck toxic vapors out of the air before anyone breathes them in. That’s a textbook example of what engineering controls are, eliminating the hazard at the source.

Now imagine if that hood didn’t exist, and the solution was just… wear a better mask. Doesn’t sound so safe anymore, right?

2. Guardrails on CNC Machines

In manufacturing, CNC machines can spin at mind-blowing speeds. Sharp tools, hot surfaces, and fast motion make them mini danger zones. But add an automatic shut-off when the door opens, and voilà, you’ve applied an engineering control!

This is where understanding what are engineering controls help companies reduce injuries and improve productivity. (Bonus: fewer accident reports = happier HR department.)

3. Ventilation Systems in 3D Printing Labs

Do you love 3D printing? So do we.

But here’s a fun fact: FDM printers release ultrafine particles that can be harmful if inhaled over long periods.

Smart engineers install ventilation systems with HEPA filters, which quietly work away, keeping the air fresh and lungs happy.

This is yet another answer to what engineering controls; subtle, efficient, and often invisible.

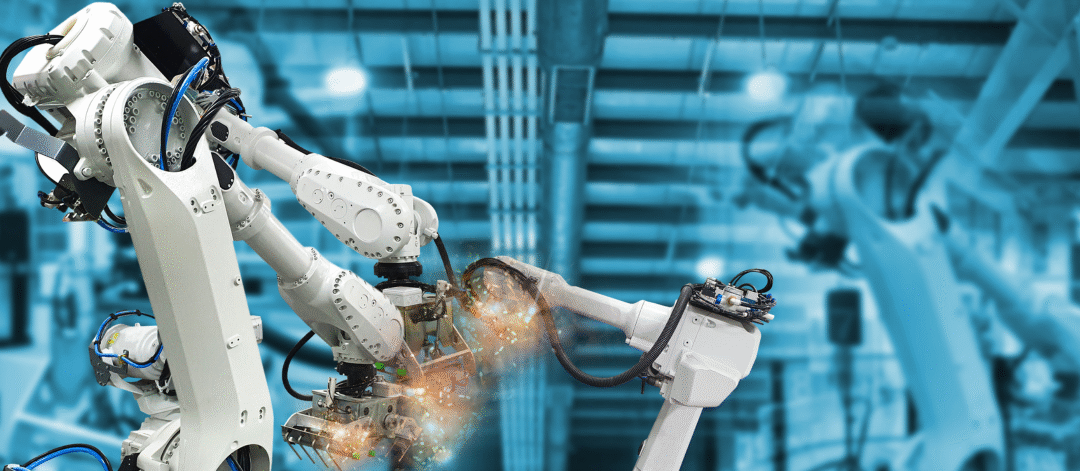

A Fun Twist: When Robots Save Humans from Hazards

Picture this: A factory uses robotic arms to dip hot metal into acid baths for surface treatment.

Humans? Nowhere near it.

That’s engineering controls at work automating the dangerous step and removing human exposure entirely. The only thing the engineer needs to worry about now is keeping the coffee machine filled.

Engineering Controls vs. Other Controls

Let’s break down the safety hierarchy to see where engineering controls stand:

| Control Type | Description | Example |

| Elimination | Remove the hazard entirely | Use water-based paint instead of solvent |

| Substitution | Replace hazard with something safer | Replace a toxic gas with a safer one |

| Engineering Controls | Isolate people from the hazard | Add a machine guard |

| Administrative Controls | Change how people work | Train staff to lift properly |

| PPE | Protect the person with gear | Wear gloves and goggles |

See how what are engineering controls fit snugly in the middle, acting like the silent bodyguard of the workplace?

Case Study: Safety Redesign in a Semiconductor Cleanroom

In one case, a semiconductor company was experiencing frequent chemical spills. Initially, they relied heavily on PPE and warning signs.

Then came the engineers.

They redesigned the storage system to have auto-locking chemical cabinets, added sensor-triggered spill containment floors, and created a closed-loop transfer system. As a result, chemical exposure incidents dropped by 80% within six months.

Now that’s the kind of answer we love to see when we ask: what engineering controls!

Why Do Engineering Controls Matter?

Let’s break it down:

- Long-Term Safety – Once implemented, they continuously reduce risk without relying on human behavior.

- Cost Efficiency – Fewer accidents = fewer lawsuits, downtime, and compensation claims.

- Smart Design – Engineers love solutions that work without needing constant attention. That’s what engineering controls do best.

- Regulatory Compliance – OSHA and other bodies love engineering controls. It’s often the first thing they look for.

Conclusion: Safer by Design

In the end, the question of what engineering controls isn’t just for textbooks—it’s for every workshop, lab, and production floor. These are the tools and designs that make our environments smarter and safer, not just through rules and reminders, but through brilliant engineering.

So next time you see a well-placed exhaust vent, a light curtain on a robotic cell, or a self-closing chemical valve—remember, that’s an engineering control quietly doing its job.

And trust us, it’s far cooler than it sounds.

FAQs:

Q1: What are engineering controls?

A: Engineering controls are safety measures built into equipment or workspaces to reduce or remove hazards. They work by physically changing the environment to make it safer.

Q2: How are engineering controls different from other safety measures?

A: Unlike PPE (personal protective equipment) or safety rules, engineering controls fix the problem at the source—so people don’t have to rely on personal actions to stay safe.

Q3: Can you give simple examples of engineering controls?

A: Yes! Examples include machine guards, ventilation systems, noise barriers, automatic shut-off switches, and enclosed chemical tanks.

Q4: Why are engineering controls important?

A: They reduce the risk of accidents and exposure by making the workplace itself safer, which is more effective than just warning people to be careful.

Q5: Are engineering controls expensive to implement?

A: Some may have higher upfront costs, but they often save money over time by preventing injuries, reducing downtime, and lowering health risks.

Q6: When should engineering controls be used?

A: They should be the first line of defense when trying to eliminate or reduce workplace hazards, before using administrative controls or PPE.