The paradigm shift in industry 4.0 has revolutionized the intelligent mechatronic systems that is an intersection of mechanical engineering, electrical engineering, computer science, and control systems. By integrating these domains, mechatronics has revolutionized industries, enabling the creation of intelligent systems that simplify complex tasks. This blog dives deep into the fascinating world of mechatronics, automation, and artificial intelligence (AI).

What is Mechatronics?

At its core, mechatronics is the fusion of mechanics and electronics to develop innovative, automated systems. From robotics to intelligent manufacturing, mechatronics plays a pivotal role in modern technology. Some defining characteristics of mechatronic systems include: Precision: High accuracy in automation processes. Interdisciplinary Approach: Combining mechanical designs with electronic controls. Adaptability: Ability to adjust to changing environments.

Intelligent Mechatronic Systems

One of the most exciting advancements in the field is the emergence of intelligent mechatronic systems. These systems use sensors, actuators, and controllers to perform tasks autonomously. Applications include:

Industrial Automation and IoT

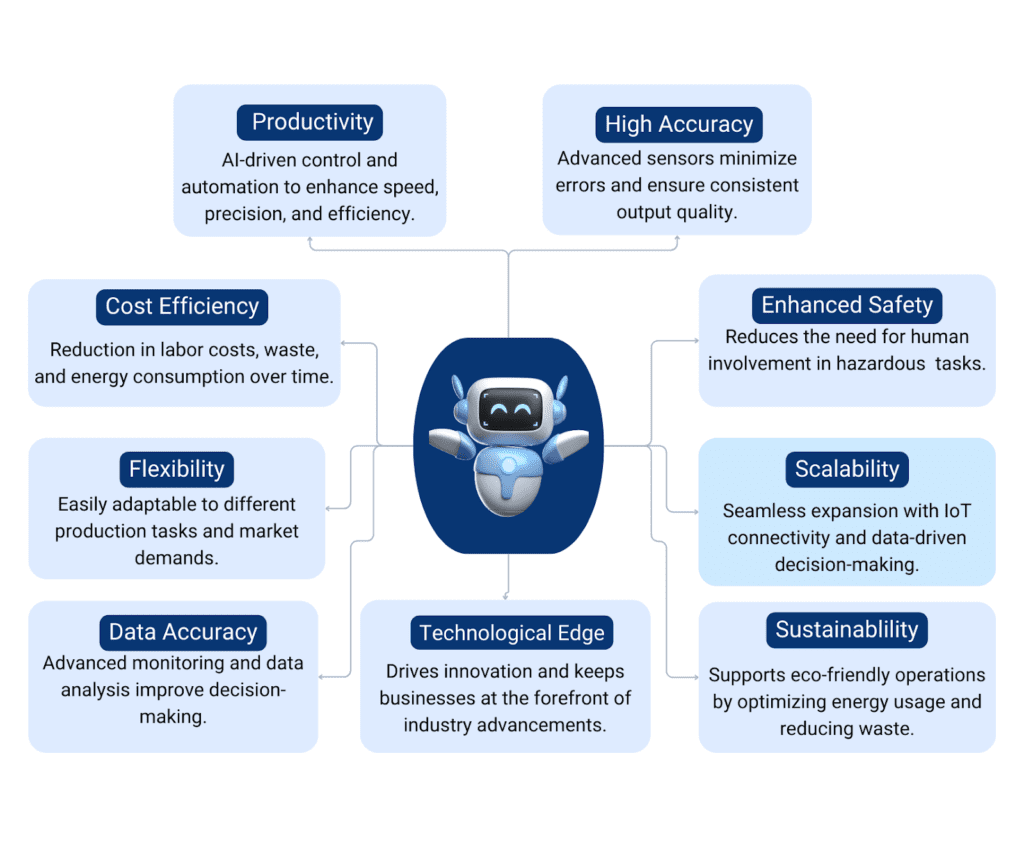

Intelligent Mechatronic Systems are transforming industrial automation by integrating IoT (Internet of Things) to create smart, interconnected production environments. These systems utilize sensors, actuators, and AI-driven controllers to monitor and optimize manufacturing processes in real time. IoT connectivity allows it to collect and analyze data from machines, predicting maintenance needs, reducing downtime, and improving operational efficiency.

Smart Warehousing

Warehousing operations are evolving with Intelligent Mechatronic Systems, which enhance efficiency through automation and smart decision-making. Automated guided vehicles (AGVs), robotic arms, and AI-driven sorting mechanisms work together to streamline inventory management and order fulfillment. These systems utilize real-time data to optimize storage space, track goods, and minimize errors. Intelligent Mechatronic Systems in smart warehousing ensure faster processing, reduced costs, and improved accuracy by leveraging advanced robotics, IoT sensors, and machine learning algorithms.

Smart Manufacturing and Industry 4.0

Industry 4.0 represents the next phase of manufacturing, where Intelligent Mechatronic Systems play a crucial role in creating highly automated, data-driven production environments. These systems integrate cyber-physical systems, IoT, and AI to enable self-optimizing manufacturing lines that respond to real-time data. It ensures precision, adaptability, and enhanced efficiency in smart factories, reducing waste and improving production quality.

By integrating AI and machine learning, intelligent mechatronic systems are becoming increasingly capable of learning and improving their functionality over time.

The Role of Automation in Intelligent Mechatronic Systems

Automation lies at the heart of mechatronics, enabling machines to perform repetitive and precise tasks without human intervention. Some notable applications include:

Automation in retail industry

In modern Intelligent Mechatronic Systems, robotics play a crucial role in assembly lines, significantly enhancing productivity and efficiency. These systems integrate mechanical components, electronics, and intelligent control algorithms to automate tasks that were once manually performed. With the help of it; industries achieve precision, speed, and consistency in manufacturing processes. Robots equipped with sensors and AI-driven control mechanisms ensure high-quality production while minimizing human intervention. The adaptability of Intelligent Mechatronic Systems allows factories to reprogram and reconfigure robots for different tasks, making automation more versatile and scalable.

Smart Mobility

Intelligent Mechatronic Systems are revolutionizing the automotive industry by enabling smart mobility solutions, enhancing vehicle automation, and improving safety. These systems integrate advanced sensors, AI-driven control mechanisms, and IoT connectivity to power autonomous vehicles, electric cars, and adaptive driver-assistance technologies. Intelligent Mechatronic Systems optimize fuel efficiency, enable predictive maintenance, and enhance vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communication. From self-driving cars to AI-powered braking and steering systems, these innovations are making transportation safer, smarter, and more efficient.

Manufacturing Aerospace Industry

The aerospace sector benefits immensely from Intelligent Mechatronic Systems, particularly in drones and aircraft equipped with automated navigation systems. These systems utilize advanced control algorithms, GPS, and inertial measurement units to ensure precise and stable flight operations. It enhances mission capabilities by enabling autonomous flight, obstacle avoidance, and adaptive responses to changing environmental conditions. In commercial and defense applications, drones leverage it for surveillance, delivery services, and reconnaissance missions. With continuous advancements, these systems are making aerospace operations more efficient, reliable, and intelligent.

Automation not only improves efficiency but also reduces costs and errors, making it a game-changer for businesses worldwide.

AI and Machine Learning in Intelligent Mechatronic Systems

Artificial intelligence and machine learning have transformed the capabilities of mechatronic systems. These technologies allow systems to have these advancements in them:

Learning Algorithms

Intelligent Mechatronic Systems play a vital role in predictive maintenance by analyzing real-time machine data to anticipate failures before they occur. These systems leverage AI, machine learning, and sensor technologies to monitor equipment performance continuously. By processing vast amounts of operational data, it detects anomalies, predicts potential breakdowns, and schedules maintenance proactively, reducing downtime and operational costs. This data-driven approach enhances system reliability, making industries more efficient and resilient. With Intelligent Mechatronic Systems, businesses can optimize maintenance strategies, extending the lifespan of machinery and improving overall productivity.

Naturalistic Decision-Making

Smart systems powered by Intelligent Mechatronic Systems can adapt to changing conditions by analyzing environmental inputs and making informed decisions in real-time. These systems use advanced control algorithms and AI-driven processing to optimize performance in dynamic settings. Whether in industrial automation, healthcare, or autonomous vehicles, it enhances decision-making by responding to uncertainties, minimizing errors, and improving efficiency. Their ability to self-adjust based on real-time data makes them invaluable in applications requiring precision, safety, and adaptability. By integrating this, industries can achieve smarter automation and better operational outcomes.

Human-Machine Interaction

Devices like voice-controlled assistants demonstrate how Intelligent Mechatronic Systems enhance human-machine interaction. These systems utilize speech recognition, natural language processing, and AI-driven responses to understand and execute user commands. It improves accessibility and convenience, allowing users to control smart homes, operate machinery, and interact with technology seamlessly. Advancements in haptic feedback, gesture recognition, and AI-driven personalization are making human-technology interaction more intuitive, efficient, and user-friendly. As these systems evolve, they will continue bridging the gap between humans and machines, creating a more connected and intelligent future.

Examples of AI-driven mechatronic applications include Amazon’s robotics systems and self-learning industrial robots.

Mechatronics Careers

Pursuing a degree in mechatronics engineering opens doors to diverse career opportunities. From research in intelligent mechatronic systems to designing smart devices, the possibilities are vast. Popular topics of study include:

Cybersecurity and mechatronics:

A growing field that ensures the safety of automated systems.

Robotics vs. mechatronics:

Understanding the subtle differences and overlaps.

Master’s Degree in mechatronics:

Advanced education opportunities worldwide.

Some of the best programs are offered by institutions like MIT and Georgia Tech, known for their cutting-edge research in mechatronics.

Mechatronics Technician Careers

The demand for skilled mechatronics technicians and engineers is steadily rising. Here’s a snapshot of salaries:

- Mechatronics Technician Salary:

Averages $55,000 annually in the U.S.

- Engineering Mechatronics Salary:

Can range between $70,000 to $120,000 based on experience and location.

Things to Make in Mechatronics

For students and enthusiasts, mechatronics offers endless possibilities for hands-on projects. Some ideas include:

- Smart Irrigation System: Utilizing soil moisture sensors and relays.

- Autonomous Robots: Robots for home cleaning or delivery.

- AI-Powered Drones: Equipped with cameras and real-time analytics.

These projects not only enhance practical knowledge but also pave the way for innovative solutions.

Mechatronics Bay area Specialized Companies

The Bay Area is home to many companies pushing the boundaries of mechatronics. Firms specializing in robotics, automation, and IoT (Internet of Things) solutions include:

- Halla Mechatronics:

Focused on automotive mechatronics.

- Mechatronic Solutions Inc:

Experts in industrial automation.

- Amazon Robotics:

Revolutionizing logistics with robotic solutions.

These companies offer exciting opportunities for professionals and graduates in the field.

Future Trends in Mechatronics

The field of mechatronics is evolving rapidly, with trends such as:

- Integration with IoT: Smart factories powered by interconnected devices.

- Sustainability: Eco-friendly designs in automation systems.

- Cybersecurity: Protecting automated systems from digital threats.

These advancements highlight the importance of staying updated on industry developments.

Conclusion

Mechatronics is not just a field of study; it’s a driving force behind the technological advancements shaping our world. Whether you’re researching intelligent mechatronic systems or exploring job opportunities in mechatronics engineering, this domain offers endless possibilities. Devomech solutions offer intelligent mechatronics systems that are innovative enough to bring revolution in a technological world. From automation to AI and machine learning, the future of mechatronics is brighter than ever.

FAQ’s:

1. How does Devomech Solutions incorporate Intelligent Mechatronic Systems in its projects?

Devomech Solutions integrates Intelligent Mechatronic Systems in automation, IoT, and product development to optimize industrial processes and enhance workflow.

2. What industries benefit from Devomech Solutions’ expertise in Intelligent Mechatronic Systems?

We specialize in embedded systems, industrial product designing, smart retail solutions, automotive and industrial automation, and biomedical sectors, delivering smart, automated solutions tailored to industry needs.

3. How do Intelligent Mechatronic Systems improve automation in Devomech Solutions’ products?

Our systems use AI-driven control, real-time data processing, and IoT connectivity to enhance precision, reliability, and adaptability.

4. Why should businesses choose Devomech Solutions for Intelligent Mechatronic Systems?

With innovation-driven engineering and sustainable solutions, we help businesses modernize operations and achieve long-term efficiency.